We are stewards of our Community’s water system

Consolidated owns and operates a state-of-the-art water treatment facility:

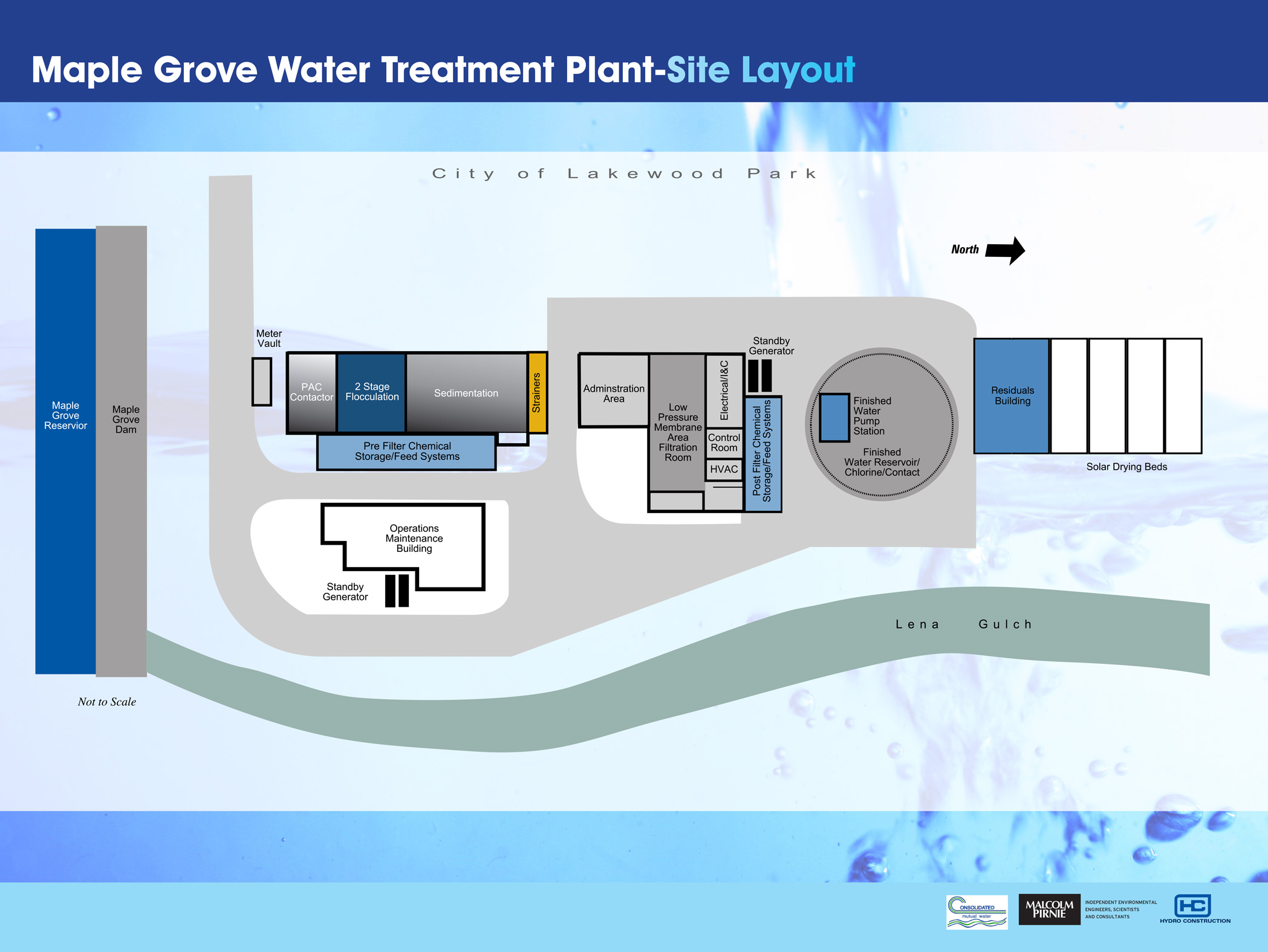

Maple Grove Water Treatment Facility (MGWTF).

MGWTF is operated by highly trained, state certified Water Treatment Facility Operators. We are proud that our facility continues not only to meet but exceed, all State and Federal Drinking Water Standards.

The current plant began service in 2008. The new MGWTF can treat and produce 15 million gallons of high quality, clean water per day, and the plant is expandable to treat 18 plus million gallons per day. The MGWTF will serve our customers well into the future for both water quality and demand.

The Treatment Process

Step One: Raw Water

Untreated (Raw) water comes from Clear Creek, Coal Creek, and Denver Water to our plant through a series of pipelines, canals, and reservoirs. Multiple water sources and many storage facilities allow Consolidated the ability to blend and switch sources as needed to attain optimum water quality.

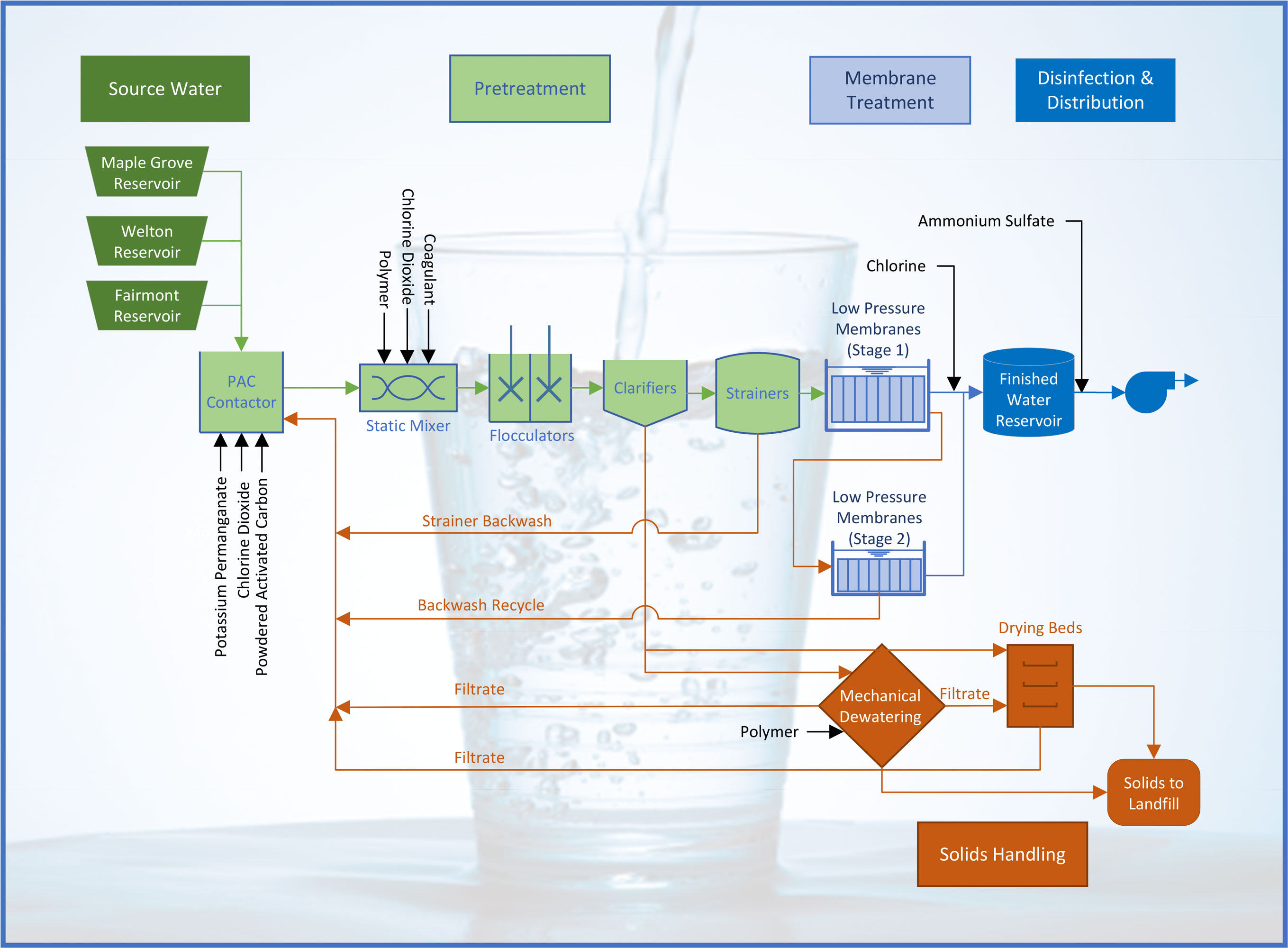

Step Two: Pre-Treatment

The pre-treatment contact basin allows the raw water contact time with additives that assist with the removal of iron, manganese, and any taste, or odor that may exist before the raw water enters the next stage of treatment: called coagulation.

Step Three: Coagulation

Following pre-treatment, raw water enters the coagulation stage. This stage is the first step in the primary treatment process. During this stage, additives contact the water through a rapid mixing process and neutralizes the naturally-occurring forces that keep the smallest particles apart, in preparation for the water moving into the next stage: called flocculation.

Step Four: Flocculation

In the flocculation stage, water is mixed gently for an extended period by rotating large, submerged paddles wheels in the flocculation basins. This part of treatment process allows the smaller particles to collide with each other creating larger particles called floc. The water then exits the flocculation basins and enters the sedimentation basins.

Step Five: Sedimentation

The primary function of the sedimentation basins is to prepare the water for filtration. In the sedimentation basins, water movement settles down which allows floc particles created in the flocculation stage to settle for removal. After the sedimentation stage, only very-fine particles remain, and the water is ready for filtration.

Step Six: Filtration

After the coagulation stage, flocculation, and sedimentation stages are complete; the water enters the filtration process. This treatment stage is essential in eliminating any remaining, extremely small, unsettled particles in the water. During the filtration stage, water passes through a filter membrane, removing the last, undesirable particles in the water. Our filters are state-of-the-art sophisticated membrane filters consisting of a polymer-based fiber. The filters reduce any suspended matter in the water to levels well below the Colorado Department of Health and Environment’s standards. An automated system continually monitors and cleans the filters to keep them performing at peak levels. After removal of any remaining super-fine particles, the water moves into the final treatment stage: disinfection and storage.

Step Seven: Disinfection and Storage

After filtration, the clean water is disinfected and flows to the finished, clean water reservoir before it enters the distribution system pump house.

Step Eight: Pump House

The clean, treated water is now then ready for you: our customer!

New Solids Handling building

The new Solids Handling building is located on our Maple Grove Treatment Facility (MGWT) site. The building became operational on February 7, 2020, and took 14 months to construct.

The building is a major enhancement of our MGWT; specifically, upgrading our ‘de-watering’ process for leftover solids created when our raw water is treated and converted into safe, clean drinking water.

The MGWT Solids handling project is an important update and ‘retrofit’ project for the treatment facility, and the result of this major project is three-fold:

a major reduction in heavy equipment activity and associated noise levels created by that heavy equipment when emptying solids holding bins;

significant reduction in odors emanating from the treatment facility; and,

the new solids handling de-watering process will save even more water in the treatment process and significantly reduce the water content remaining in the solids from treatment, compared to the previous treatment process, by siphoning the water from the new ‘de-watering’ process and recycling and retreating the leftover water.

This higher level of efficiency directly relates to keeping the cost of treated water we deliver to our Stockholders/Customers at reasonable rates.

Read more about the Residuals Handling building upgrades in this July, 2020 article from Rocky Mountain Water: